About

Ask a Plumber

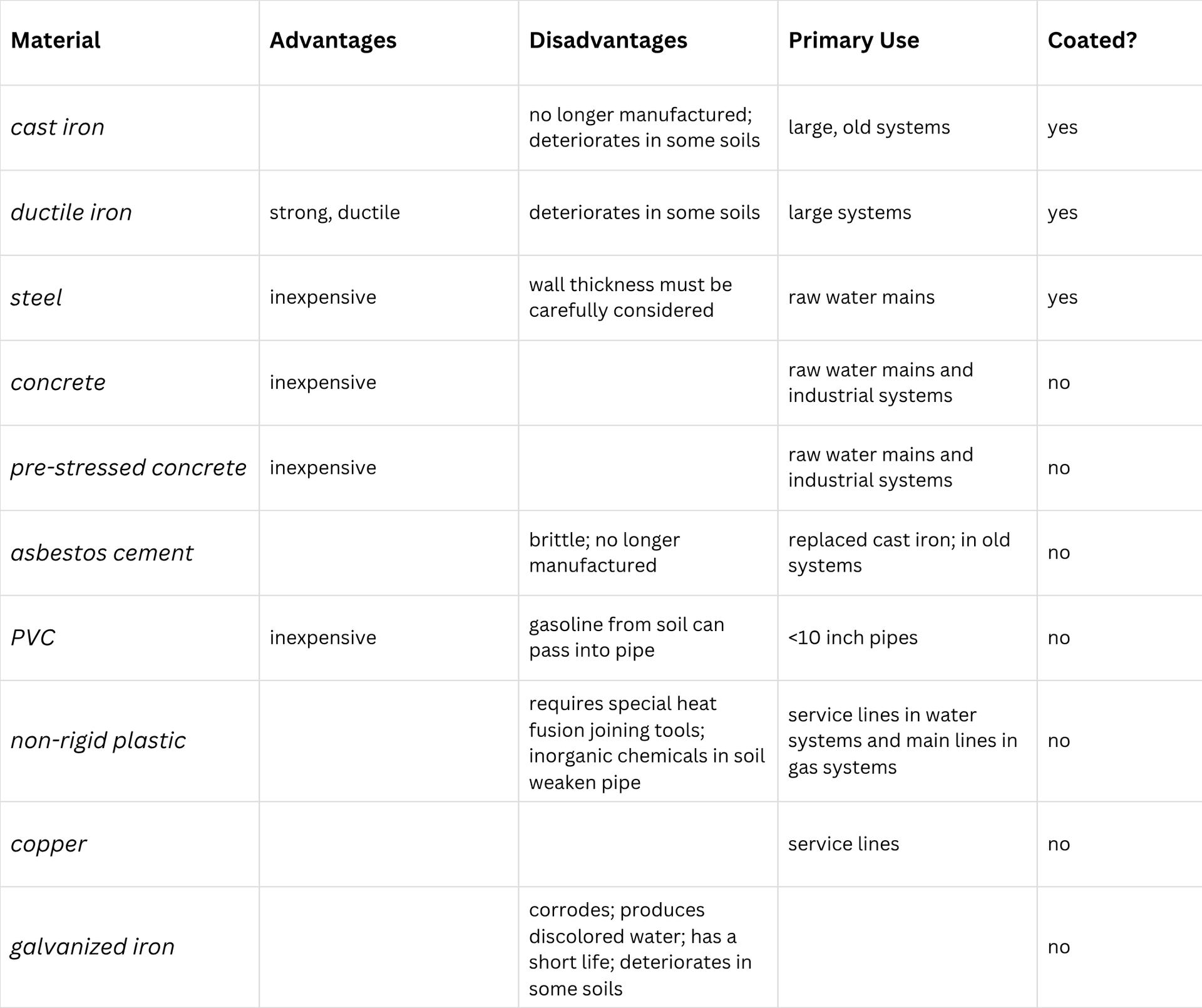

What are the types of pipe material?

How can I identify a water leak?

Step 1.

First, locate your meter box. It is generally located near the sidewalk in front of your home in a direct line with the main outside faucet. It’s important to make sure the meter box lid is uncovered and visible at all times. A black circular disc on the lid provides the signal to the meter reader with an electronic signal - a ‘radio read.’

Step 2.

Turn all water-using appliances off so that no water is being used. This means turning off all water inside and outside the house including showers, sinks, washing machines, ice makers and any appliance that use water. If you have an automatic irrigation system, turn off the controller.

Carefully remove the meter box lid by using a tool such as a large screwdriver. Stand back. There are sometimes ‘critters’ inside the box that will be startled when the lid is removed. Give them a chance to get out of the way.

The meter uses a straight-reading dial which is read similar to a cars odometer. The meter measures water use in thousands of gallons.

The small pointer or dial near the center of the meter is the flow indicator and should not move if you are not using any water inside or outside the home. If the flow indicator is moving, you may have a leak.

In leaky toilets, the flapper valve often needs to be replaced.

Step 3.

If there is no indicator and the actual meter dial hand is moving, water is running somewhere in your system and you have a leak – go to step 4.

If the hand is not moving, note the position of the hand and wait 10 minutes. Check the meter again, if it has moved, you have a slow leak - go to step 4.

If no movement is recorded, you probably don’t have a leak. The meter may not be able to detect leaks in irrigation systems or pools.

Step 4.

To isolate the leak, turn the water off to your house. Your home’s valve is usually located under the outside faucet near the front of the house. With all water turned off in the house, there should be no movement of the small pointer or any of the dials on the meter.

Step 5.

If the leak indicator or dial is still moving, water is flowing between the meter and the shut-off valve. That means you could have a leak between the meter and the valve where water enters your home. This is called the ‘service line’.

Consider that movement in your meter can also be caused by things like an automatic pool filler, a leaky irrigation valve, or an evaporative cooler. Follow this link for more information on leaks in pools.

Step 6.

Check your irrigation system. If you have leaks in your irrigation system, they may not be noticeable unless your system is running. Turn your controller on manually and walk your property looking for broken sprinkler heads, missing emitters (which will produce small streams of water) or breaks in irrigation piping or tubing. Check for leaks inside the house including toilets, washing machines, faucets, etc.

Step 7.

To check a toilet for a leak: Add 2 or 3 drops of food coloring to the water in the reservoir or tank (as shown in Figure 1). Wait 15-30 minutes. If the water in the bowl changes colors, the rubber flapper needs to be replaced. In leaky toilets, the flapper valve often needs to be replaced.

Step 8.

Congratulate yourself! You’ve just completed a leak-detection investigation.

What are the different types of pipes and how do they work?

Steel:

Galvanized steel potable water supply and distribution pipes are commonly found with nominal pipe sizes from 3⁄8 inch (9.5 mm) to 2 inches (51 mm). It is rarely used today for new construction residential plumbing. Steel pipe has National Pipe Thread (NPT) standard tapered male threads, which connect with female tapered threads on elbows, tees, couplers, valves, and other fittings. Galvanized steel (often known simply as "galv" or "iron" in the plumbing trade) is relatively expensive, and difficult to work with due to weight and requirement of a pipe threader. It remains in common use for repair of existing "galv" systems and to satisfy building code non-combustibility requirements typically found in hotels, apartment buildings and other commercial applications. It is also extremely durable and resistant to mechanical abuse. Black lacquered steel pipe is the most widely used pipe material for fire sprinklers and natural gas.

Most typical single family home systems won't require supply piping larger than 3⁄4 inch (19 mm) due to expense as well as steel piping's tendency to become obstructed from internal rusting and mineral deposits forming on the inside of the pipe over time once the internal galvanizing zinc coating has degraded. In potable water distribution service, galvanized steel pipe has a service life of about 30 to 50 years, although it is not uncommon for it to be less in geographic areas with corrosive water contaminants.

Copper:

Copper pipe and tubing was widely used for domestic water systems in the latter half of the twentieth century. Demand for copper products has fallen due to the dramatic increase in the price of copper, resulting in increased demand for alternative products including PEX and stainless steel.

Plastic:

Plastic: Plastic hot and cold supply piping for a sink Plastic pipe is in wide use for domestic water supply and drain-waste-vent (DWV) pipe. Principal types include: Polyvinyl chloride (PVC) was produced experimentally in the 19th century but did not become practical to manufacture until 1926, when Waldo Semon of BF Goodrich Co. developed a method to plasticize PVC, making it easier to process. PVC pipe began to be manufactured in the 1940s and was in wide use for Drain-Waste-Vent piping during the reconstruction of Germany and Japan following WWII. In the 1950s, plastics manufacturers in Western Europe and Japan began producing acrylonitrile butadiene styrene (ABS) pipe. The method for producing cross-linked polyethylene (PEX) was also developed in the 1950s. Plastic supply pipes have become increasingly common, with a variety of materials and fittings employed.

- PVC/CPVC – rigid plastic pipes similar to PVC drain pipes but with thicker walls to deal with municipal water pressure, introduced around 1970. PVC stands for polyvinyl chloride, and it’s become a common replacement for metal piping. PVC should be used only for cold water, or for venting. CPVC can be used for hot and cold potable water supply. Connections are made with primers and solvent cements as required by code.

- PP – The material is used primarily in housewares, food packaging, and clinical equipment, but since the early 1970s has seen increasing use worldwide for both domestic hot and cold water. PP pipes are heat fused, being unsuitable for the use of glues, solvents, or mechanical fittings. PP pipe is often used in green building projects.

- PBT – flexible (usually gray or black) plastic pipe which is attached to barbed fittings and secured in place with a copper crimp ring. The primary manufacturer of PBT tubing and fittings was driven into bankruptcy by a class-action lawsuit over failures of this system. However, PB and PBT tubing has since returned to the market and codes, typically first for "exposed locations" such as risers.

- PEX – cross-linked polyethylene system with mechanically joined fittings employing barbs, and crimped steel or copper rings.

- Polytanks – plastic polyethylene cisterns, underground water tanks, above ground water tanks, are usually made of linear polyethylene suitable as a potable water storage tank, provided in white, black or green.

- Aqua – known as PEX-Al-PEX, for its PEX/aluminum sandwich, consisting of aluminum pipe sandwiched between layers of PEX, and connected with modified brass compression fittings. In 2005, a large number of these fittings were recalled.

Am I in your service area?

We proudly serve Chattanooga, North GA, and the surrounding areas! Checkout our Service Areas Page for more detail!

Do you offer maintenance products?

South East Total Service offers maintenance products to repair and stop recurring plumbing problems. Slow drains and back ups are common annoying plumbing problems that seem to plague most properties. Common causes include grease or food build up in sink drains, hair build up in shower drains, lint and other natural material build up in laundry lines as well as roots in the main sewer line.

All of these causes can be treated and eliminated with regular use of our maintenance products.

Common signs of roots in the main line:

- Reoccurring drain problems.

- Ground settling along the pipe line.

A South East Total Service technician can determine if you have roots in the line!

ROOT X is a safe, simple and effective solution to pipeline root intrusion without hurting the tree or plant itself. The active ingredient in this product will kill only the roots with which it comes in contact and prevent their re-growth for up to one year. The environmentally safe chemical combination helps speed up the natural decomposition of roots. When mixed with water, ROOT X creates a foam that fills the entire pipe and leaves a residue above the water line to inhibit new growth.

The South East Total Service technicians will add the product and water to your system through the outside clean out access. Some situations, such as root blockage, require mechanical root cutting equipment to be most effective. The use of this equipment alone is only a short term solution because, as with pruning, the new growth comes back bigger and stronger where it was cut. The bigger, stronger roots will eventually destroy the line. An excavation and line replacement is the only way to completely solve that problem. An annual treatment or maintenance program will always cost less than replacing a broken line.

For more information on ROOT X treatments or maintenance programs, call SETS!